Plain Sawn vs. Quarter Sawn vs. Rift Sawn Lumber

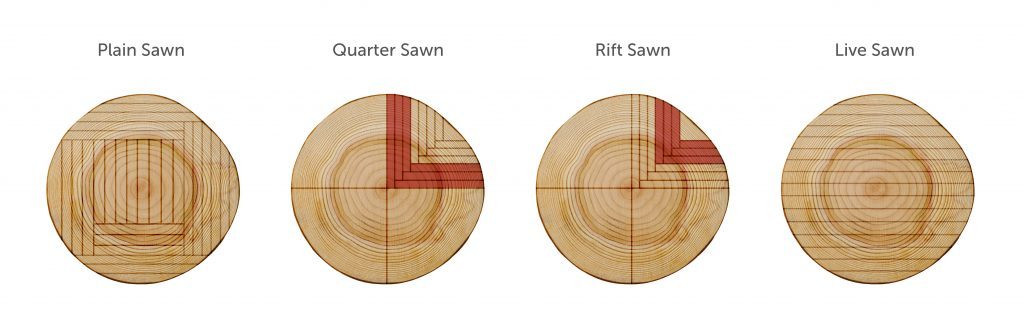

Each type of lumber is dependent on how the log is oriented and cut at the mill. The result is a particular orientation of the annual growth rings on the end grain of a board; this is what determines the type of lumber.

Plain Sawn

Most common, least expensive

At the sawmill, plain sawn lumber is cut into parallel planks through the center of the tree. Looking at the annual growth rings at the end of a plain sawn board reveals that they are arranged at less than 45 degrees or in a frown shape. The surface of the board has the famous cathedral pattern of peaks in the wood grain.

Plain sawn is the least expensive and most common lumber you will find because milling is faster and there is minimal waste involved.

There are some disadvantages as plain sawn wood does have some structural drawbacks. Due to the tangential grain, there is a higher chance of cupping and twisting especially if there is moisture present.

Quarter Sawn

More expensive than plain sawn material

Quarter sawn wood is more expensive because it is more labor intensive to produce and the manufacturing process produces more waste than plain sawn lumber.

At the sawmill, each log is sawed at a radial angle into four quarters, hence the name, then each quarter is plain sawn. The annual growth rings at the end of a quarter sawn board intersect the face of the board at a 60 to 90 degree angle, making the grain pattern on the face of the board is straight. Dramatic flecking is also present in red oak and white oak.

In addition to the desirable grain pattern this type of wood is the most stable. The board won’t cup because the annual growth rings are perpendicular to the face, and it is more resistant to moisture penetration and less prone to surface checking and raised grain.

Rift Sawn

Most expensive, least common

Rift sawn boards are manufactured by milling perpendicular to the log’s growth rings producing a linear grain with no flecking. The annual growth rings are typically between 30 to 60 degrees. This is a time consuming process that produces large triangles of waste left from between each board. The result makes rift sawn lumber is costly to produce.

Rift sawn lumber is the most dimensionally stable cut of lumber available, and it is used for applications that require straight lined grain through and through. It is ideal for custom furniture makers to use for table, chairs, and other furniture legs that benefit from having all exposed sides with the same linear appearance.

See examples of the different types of flooring cuts.